质量管理 QUALITY MANAGEMENT

•我们的宗旨Our Vision :

• 客户至上,为客户提供优质产品和服务,为客户创造更多的价值.

• Customer first, provide high quality and excellent service for customer, create more value for customer.

•我们的质量目标Our qual ity target:

• 满足客户的需求,提供零缺陷产品。

• Fulfill customer requirements, provide Zero defect product as our final target.

质量管理 QUALITY MANAGEMENT 质量控制QC

•按照质量检验计划相应的控制点进行质量检验。

• Quality inspection is implemented according to ITP's control points.

•我们重点关注过程控制和检验,从原材料检验开始,到材料切割下料、焊前拼装、焊接过程的监控、焊后的检 验、无损探伤、机加工毛坯检验,机加工的终检、装配检验、喷砂油漆检验、包装检验等实施全程质量监控。

• We're focus on quality control in process, from raw materials inspection to cutting, fit-up before welding, welding supervision during welding, inspection after welding, NDE, dimension check before machining, machining inspection at final, assembling inspection, sandblasting and painting, packing inspection etc., all inspection & supervision through fabrication. •发现质量问题快速纠正或者NCR形式解决。

• Quality problems are found to be quickly corrected or solved in the form of NCR.

•每日都有质量检验数据统计,每月进行质量数据的分析汇总,并制作改进机会。

• Quality inspection date are recorded daily, quality date analysis monthly and find improvement chance..

生产管理和制造工艺

PRODUCTION MANAGEMENT FABRICATION PROCESS

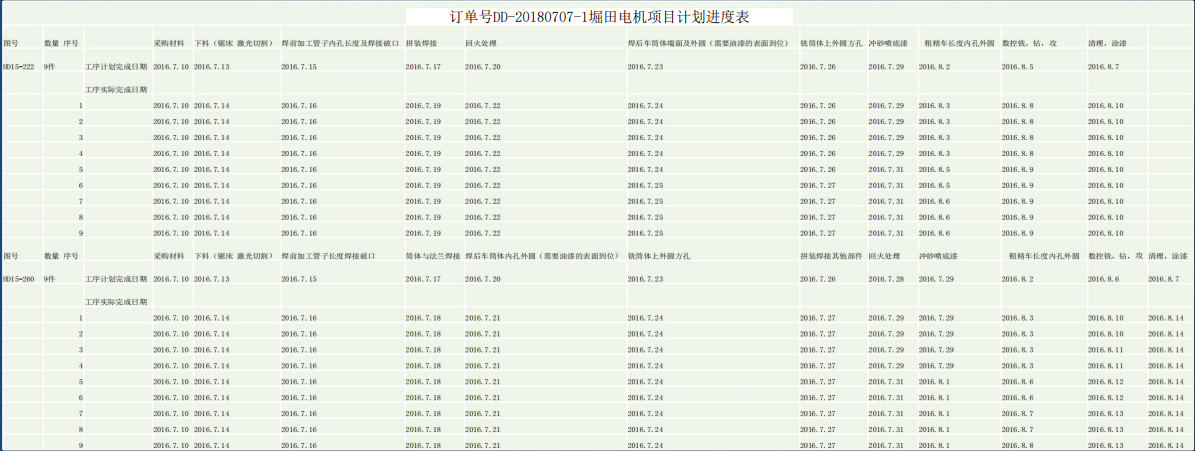

• 在产品制作前制定详细的产品制作计划,在制作过程计划跟踪和调整,确保最终的交货期。

• Fabrication plan in detail is prepared before fabrication, follow up the schedule and adjust in fabrication process and ensure the final delivery.

生产管理和制造工艺

PRODUCTION MANAGEMENT FABRICATION PROCESS

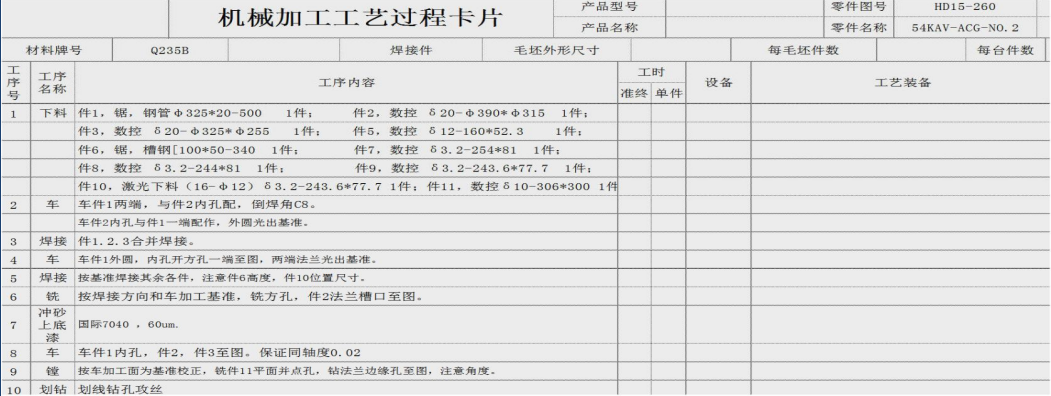

• 每个零件在制作前制定制造工艺卡,操作者严格按照工艺卡执行,过程有检验员跟踪检验,确保产品最终质量

• Fabrication process card of each component is prepared before fabrication, operator follows strictly as process card, QC checks in process and ensure the quality at final.

Copyright © 2018-2023 江阴市强德真空机械有限公司 版权所有 地址:江阴市龙定路71号 备案号: 网站地图